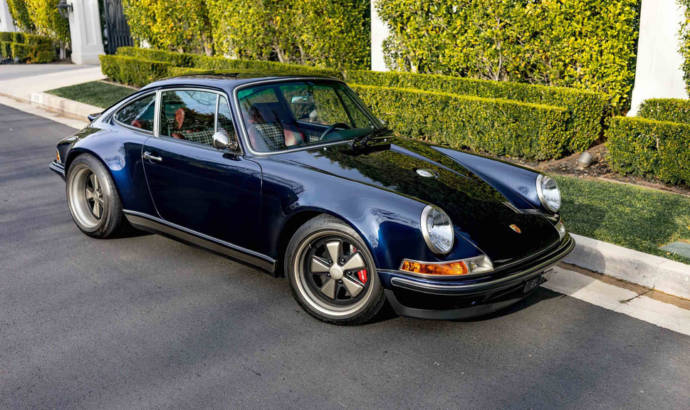

Singer is renowned for its expertise when it comes to restoring old Porsche’s. Delivering true masterpieces wouldn’t be complete without an engine that follows the specifications of its original manufacturer.

So, Singer Vehicle Design announces details of a new level of restoration and modification services commissioned by three of its clients for their air-cooled Porsche 911s. To meet the high-performance and light-weighting goals required for the restorations, Singer has undertaken a performance research study with Williams Advanced Engineering, part of Williams Grand Prix Engineering Group, and engaged the celebrated motorsports concern to engineer technical modifications and components for these restored Porsche 911s.

The first fruit of this work is a modified, naturally aspirated, air-cooled, flat-six Porsche 911 engine with a 4.0L capacity, four-valves per cylinder and four cam-shafts, rated at 500HP.

The engine will power a 1990 Porsche 911 currently being restored for long-term Singer client, Scott Blattner.

Beginning with the Mezger-designed Porsche 3.6L engine from the 1990 911, the resulting specification is as follows:

– 500HP

– Four-valve cylinder heads

– Engine speed range extended beyond 9,000 rpm

– Dual-oil circuits

– Cylinders and pistons with titanium con-rods

– Aluminum throttle bodies with carbon fiber trumpets

– Upper and lower injectors for improved performance

– A carbon fiber air-box with active multi-stage resonator chamber for mid-range torque optimization

– Inconel and titanium exhaust system optimized for thermal performance

– CFD optimized and enlarged engine cooling fan

– Ram air induction system with pressure recovery in intake plenums

– Lightweight materials, including titanium, magnesium and carbon fiber are used extensively to reduce component mass and vehicle weight.