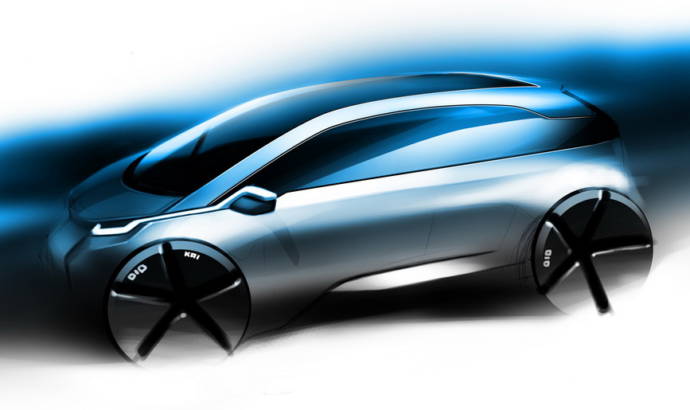

The Bavarian company has released images and details of the BMW Megacity which will be an electric four-seater expected to get launched on the market in 2013.

The 2013 BMW Megacity also known as the MCV is destined for urban mobility and will feature an electric motor producing 100 kW and a battery pack plus a small combustion engine that will serve as a range extender.

As far as architecture the 2013 BMW Megacity will concentrate towards lightweight materials with its LifeDrive concept that uses Carbon Fibre Reinforced Plastic, which is twice as light as aluminium yet strong as steel, to offset the typical 250 to 350 Kg additional weight that gets added by the car’s electrical drive system.

This LifiDrive concept is composed of two independent modules : the Drive module integrates the battery, the drive

system and structural and crash functions while the Life module is is the extremely lightweight passenger cell made from

CFRP.

BMW press release :

Munich. The BMW Group is once again breaking new

ground with the Megacity Vehicle (MCV), due to come onto the market in

2013: “The Megacity Vehicle is a revolutionary automobile. It

will be the world’s first volume-produced vehicle with a

passenger cell made from carbon. Our LifeDrive architecture is helping

us to open a new chapter in automotive lightweight design. Indeed,

this concept allows us to practically offset the extra 250 to 350

kilograms of weight typically found in electrically powered

vehicles.” says Klaus Draeger, Member of the Board of Management

for Development.

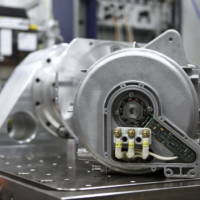

“The drive system remains the heartbeat of a car, and that also

applies to electric vehicles,” said Draeger. “Powertrains

also remain a core area of expertise of Bayerische Motoren Werke.

Electromobility and the hallmark BMW driving pleasure make an

excellent match, if you go about things the right way. For this reason

we are developing the powertrain for the Megacity Vehicle in-house

– that includes the electric motor, the power electronics and

the battery system.”

The electrification of a vehicle requires new concepts in vehicle

architecture and body construction in order to exploit the potential

of the new emission-free drive system to optimum effect. With the

revolutionary LifeDrive concept, the BMW Group engineers are

developing the car’s architecture from scratch and adapting it

to the demands and conditions of future mobility. The goal: to offset

the additional weight of an electric vehicle – typically 250 to

350 kilograms. To this end, the BMW Group is focusing on the

innovative high-tech material carbon fibre reinforced plastic (CFRP).

The LifeDrive concept consists of two horizontally separated,

independent modules. The Drive module integrates the battery, drive

system and structural and crash functions into a single construction

within the chassis. Its partner, the Life module, consists primarily

of a high-strength and extremely lightweight passenger cell made from

CFRP. Furthermore, the new vehicle architecture opens the door to

totally new production processes which are both simpler and more

flexible, and use less energy.

The BMW Group is also aiming to be the force behind the best drive

systems over the years ahead – systems boasting outstanding

efficiency, performance and smoothness, even if it is electricity

rather than fossil fuels that are converted into propulsion. To this

end, the BMW Group is vigorously driving forward the technical

development of electric powertrains. The BMW Group’s centre of

expertise for electric drive systems brings together development,

manufacturing and procurement specialists under one roof. All their

efforts are focused on the implementation and typically BMW

interpretation of the new generation of drive systems. Ultimately,

electric vehicles not only provide a zero-local-emission and low-noise

form of propulsion; their ability to deliver a totally new and

extremely agile driving experience is also impressive.

The new architecture of the MCV also gives the vehicle designers

additional freedom when it comes to creating a new aesthetic for

sustainable urban mobility solutions.

02 Jul 2010

0